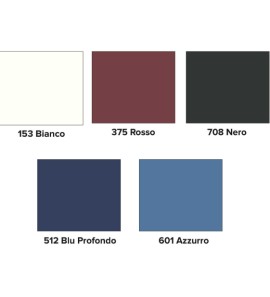

STANDARD PLUS ANTIFOULING 0.750 ML

Self-polishing antifouling, formulated with copper salts, usable on wooden boats,

medium speed iron and fiberglass up to 30 knots. It is recommended to apply at least 2 coats of the product.

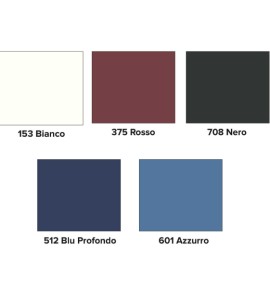

STANDARD PLUS ANTIFOULING STC 0.750 ML

New iron hulls. Apply a coat of EPOZINC 2C on sandblasted iron at grade 2-2.5 and let it dry for 12-24 hours. Then apply 2-3 coats of EPOFOND AM / 9 at intervals of no more than 24 hours from each other (at least 6-8 hours), then 2 coats of STANDARD PLUS STC Bianca antifouling 18-24 hours apart. other.

New wooden fairings. Apply a coat of CROMOMINIO-AT widely diluted. Follow with two coats of SOLVER PRIMER, leaving 24 hours between coats. Then apply 2 coats of STANDARD PLUS STC White antifouling at least 12-24 hours apart.

New hulls in fiberglass or plastic

. Degrease with detergents and water and rinse. Lightly sand with fine abrasive papers and dust. Apply a coat of EPOFOND AM-9 or POLIFIBER PRIMER and after 24 hours sand with fine sandpaper. Then apply with 2 coats of STANDARD PLUS STC Bianca 12-24 hours apart.

Aluminum or light alloys .

Degrease the surface well with Thinner 765. Then apply a coat of EPOFOND AM-9 and let it dry for 8 hours but not more than 24 hours. Apply 3 coats of SOLVER PRIMER 24 hours apart, then 2 coats of STANDARD PLUS STC White antifouling 12-24 hours apart

Fairings already painted .

- If the old antifouling is in good condition, compatible, and well anchored, it will be sufficient to apply one or two coats of SOLVER PRIMER before overcoating with 2 coats of STANDARD PLUS STC White antifouling at a distance of at least 12-24 hours between one coat and the other.

-If the old antifouling is not in good condition, restore the support by removing the residues of the old paint with a scraper or brush and then proceed as recommended for new fairings.

| Application | Roller and spray brush |

| Brush-roller dilution | Ready to use or with max 5% Thinner 400 |

| Spray dilution | 10% Thinner 400 |

| Touch dry | 3-4 hours (20 ° c) |

| Placing in the water | Min 24-48 hours |

| Overcoating time | 18-24 hours (20 ° c) |

| Application temperature | Between +10 c and +40 c |

| Relative humidity | Less than 80% |

| Recommended dry thickness | 50-60 microns per hand |

| Theoretical yield m2 / liter | 10-12 |

| Typology | Single component |

| Type of binder sol a | Natural modified resins |

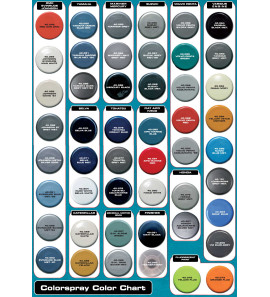

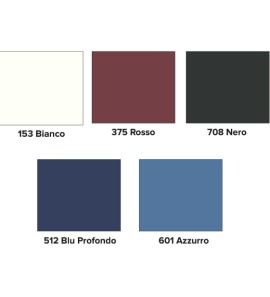

| Specific weight kg / l (± 0.05) | 1,760-1,810 according to the color |

| Dry residue (volume) | 42% |

| Viscosity ford | 12 sec. (Ø8 at 20 ° C) |

| Storage (+ 10- + 30c) | 12 months sealed containers |

Recensione

No customer reviews for the moment.

Related Product

13 other products

copy of MARLIN ANTIFOULING TF 2.5LT SELF-POLISHING

Self-polishing antifouling based on special resins, cuprous oxide and anti-slime agents,

in the colors: oxide red, black and sky blue.

In the colours white and sky blue it is copper-free and is therefore also suitable for light alloy hulls.

MARLIN 303 SELF-POLISHING ANTIFOULING 2,5LT

Marlin Self-polishing antifouling for boats

MARLIN ANTIFOULING VELOX PLUS 0.250ML

Specific antifouling for immersed metal parts such as propellers, stern drives, shaft lines.

MARLIN TF 0.750 SELF-POLISHING ANTIFOULING

Self-polishing antifouling based on special resins, cuprous oxide and anti-slime agents,

in the colors: oxide red, black and sky blue.

In the colours white and sky blue it is copper-free and is therefore also suitable for light alloy hulls.

ANTIFOULING CONTENDER STC WHITE 0.750

Hard antifouling, containing copper thiocyanate with high antifouling power.

MARLIN 303 SELF-POLISHING ANTIFOULING 0.750 LT

Marlin Self-polishing antifouling for boats

MARLIN ANTIFOULING TF 2.5LT SELF-POLISHING

Self-polishing antifouling based on special resins, cuprous oxide and anti-slime agents,

in the colors: oxide red, black and sky blue.

In the colours white and sky blue it is copper-free and is therefore also suitable for light alloy hulls.

MARLIN FLEXY ENAMEL FOR INFLATABLE BOATS 0.5L

Ready-to-use enamel for the restoration of rubber dinghy tubes

available in white or gray